Offline programming of 3d stampings or formed parts minimizes machine downtime required for programming as the machine tool itself is not required to have to teach the cutting program.

Mazak laser programming software.

The import functions of the 3d model data from.

Off line programming system does not reduce the beam on time of the laser processing machine.

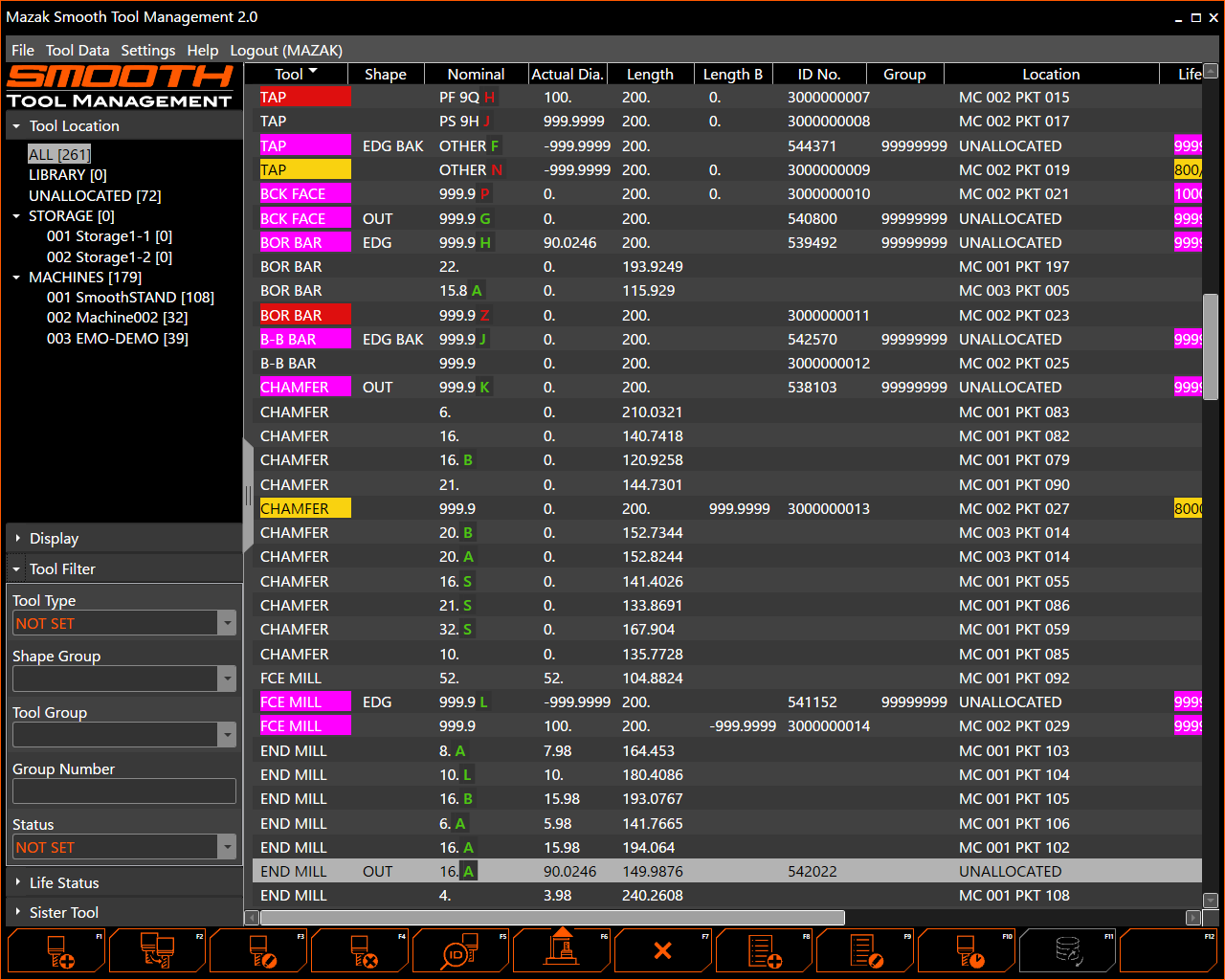

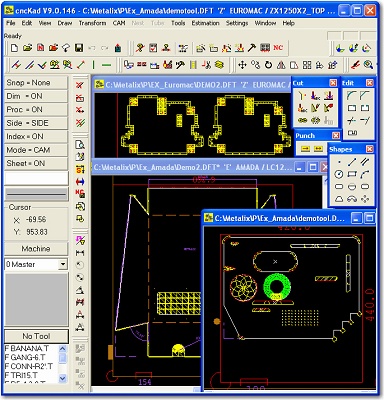

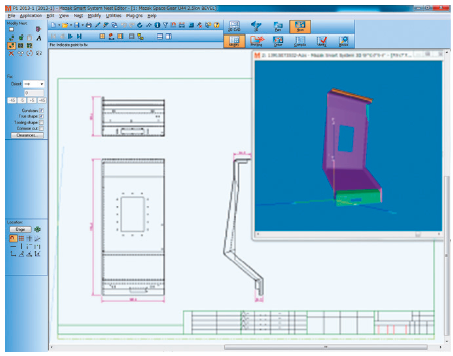

Mazak smart system is a pc based 2d cad cam system that enables laser operators to eliminate manual non productive steps in sheet metal processing and go into production quicker than ever before.

Mazak optonics corporation is a major supplier of laser cutting systems offering 50 laser models and leading the industry in the implementation of emerging laser technologies.

Mazak training courses offered.

It allows users to create accurate drawings while simultaneously preparing the geometry for processing no matter what the programmer s experience.

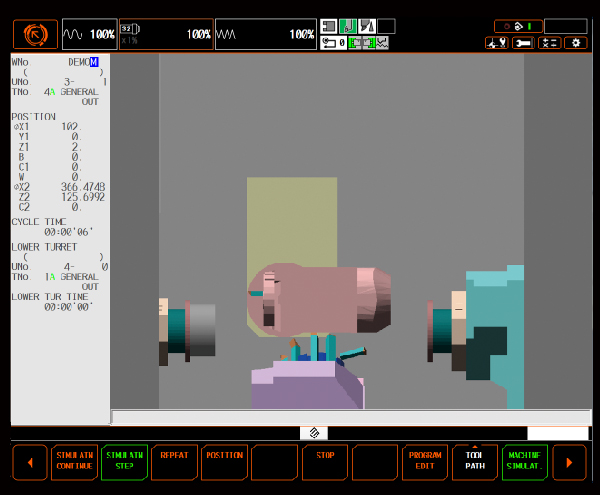

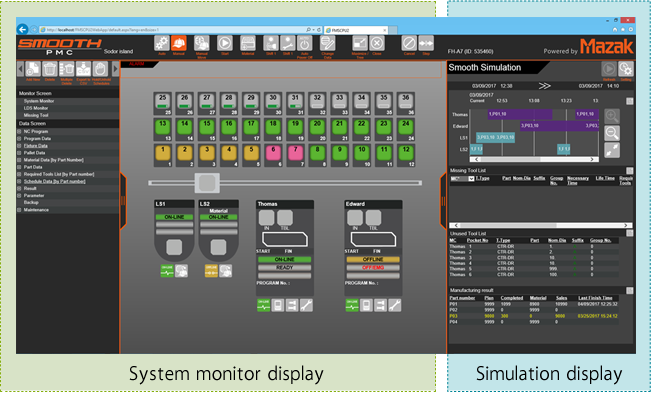

Ai powered programming for the most complex parts the next generation of mazatrol smooth cnc technology the mazatrol smoothai control and associated software packages deliver powerful digital enhancements that add efficiency and value throughout the machining process with the power of artificial intelligence ai machine learning and advanced.

About mazak optonics corporation.

This unique system also has been used on mazak lasers for almost 30 years.

Able to optimize a mazak laser machine s performance more than any other software package offered.

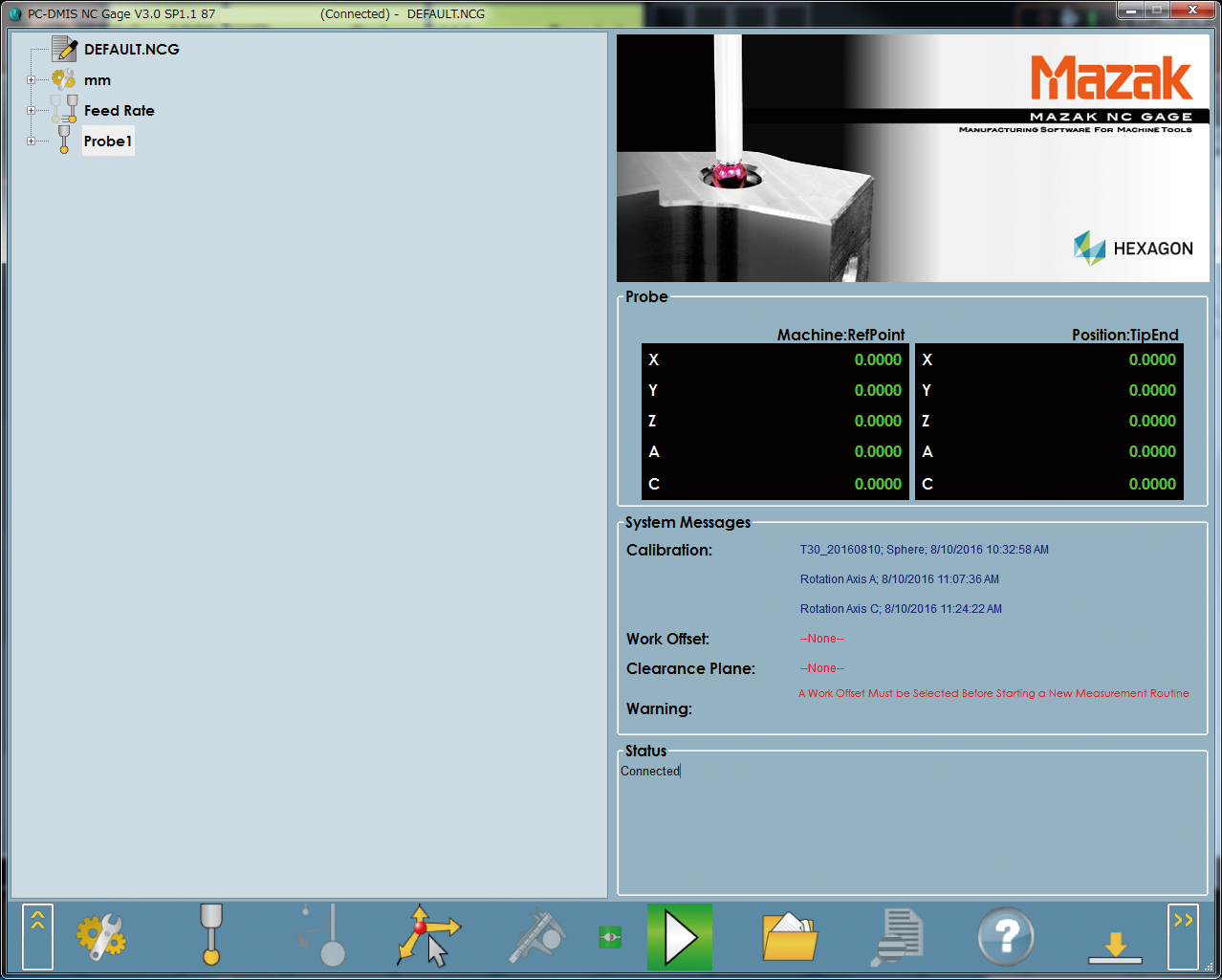

Mazak laser processing machine cnc systems.

Our engineers are able to assist you with your cutting and programming questions.

Smart system 2d cad cam software solution.

Basic 2d operator course.

The optiplex nexus fiber is an affordable solution that delivers cutting edge technology.

The revolutionary mazatrol cnc developed exclusively by mazak was first used on metal cutting machine tools in 1981.

For additional assistance please contact the mazak software department at 1 888 mazak us.

Equipped with mazak s intelligent functions rugged construction and now the mazatrol previewg control offering outstanding value.

Maximize flexibility in nest programming through a variety of techniques allowing for highly efficient nesting utilization on a single sheet.

The mazak applications department offers both machine and software programming training classes.

Training is available at our technology center located in elgin il.

Off line programming will reduce the beam on time of the laser processing machine.

Applications support is also available for mazak programming software packages.

The operation can easily produce a drawing nesting program check and cnc program.

Over 300 customers receive hands on training annually on their mazak laser cutting machines in our elgin technology center.

The previewg advantage optiplex nexus 3015 fiber.